UNIVERSAL ROBOTS

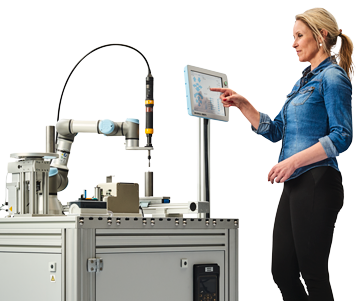

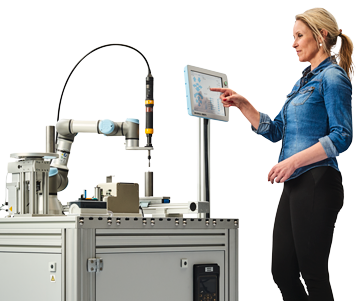

The UR3e collaborative robot is a compact 6-axis industrial robot for use in tight workspaces as a companion to workers performing light assembly production tasks. Even when space is constrained this bench-top UR3 e-Series collaborative robot, or cobot, makes incremental automation possible because in most cases it requires no safety guarding, and doesn't have to be placed permanently in one location.

Each of the Universal Robots UR3e's 6 axes, or elbows, safely rotates 360 degrees, but the final axis, or the robot's wrist, spins infinitely making the UR3e the optimal safe and collaborative robot model for quickly automating many tool fastening applications. The robot's reach radius extends to 19.7 inches, lifting a payload of up to 6.6 lbs.

See more specifications here.

Other Universal Robots collaborative robot models include the precision

UR5e cobot which lifts up to 11 lbs within a reach radius of just under 34"; the workhorse

UR10e cobot which lifts up to 27.5 lbs within a reach radius of over 51"; and the powerfully built

UR16e which lifts over 35 lbs within a reach radius of more than 35".

RAPID SETUP

Getting started with the UR3e cobot is a quick process. Initial orientation and module-based training is provided tuition-free on the web in the Universal Robots Academy, requiring a total time investment of around 87 minutes.

FLEXIBLE DEPLOYMENT

Then, when your robot is delivered, unpacking, mounting, and programming this industrial robot's initial movements is frequently accomplished in less that 60 minutes. The cobot's small size, flexibility, and programming ease allow you to retask it as needed.

Some tasks require greater touch sensitivity than others, an enhanced capability incorporated in the redesigned e-Series robots, each of which includes a force torque sensor which delivers human-like touch sensitivity.

Additionally, some tasks require a high level of pose repeatability, something the new eSeries delivers at +/- 0.03mm, or about 1/12,000th of an inch.

EASY PROGRAMMING

Training at a greater depth is available locally at either of the two HTE Automation Universal Robots Authorized Training Centers, one in St. Louis Missouri, and another in Lenexa Kansas, in the Kansas City metropolitan area.

The Universal Robots Teach Pendant provides an elegant means of teaching the robot what you want it to do. Once the 2-day UR Core Training class has been completed, students will have a significant matery of this important tool.

HTE Automation works together with Universal Robots and the Universal Robots Plus program partners to help manufacturers in Kansas, Missouri, and Illinois operate more efficiently, thereby becoming more competitive.

Call us at 800-444-4831 to explore how we can work together to accelerate your company's productivity.

The UR3e collaborative robot is a compact 6-axis industrial robot for use in tight workspaces as a companion to workers performing light assembly production tasks. Even when space is constrained this bench-top UR3 e-Series collaborative robot, or cobot, makes incremental automation possible because in most cases it requires no safety guarding, and doesn't have to be placed permanently in one location.

The UR3e collaborative robot is a compact 6-axis industrial robot for use in tight workspaces as a companion to workers performing light assembly production tasks. Even when space is constrained this bench-top UR3 e-Series collaborative robot, or cobot, makes incremental automation possible because in most cases it requires no safety guarding, and doesn't have to be placed permanently in one location.